Distance Between Lead-In/Out - Is this controlled somewhere?

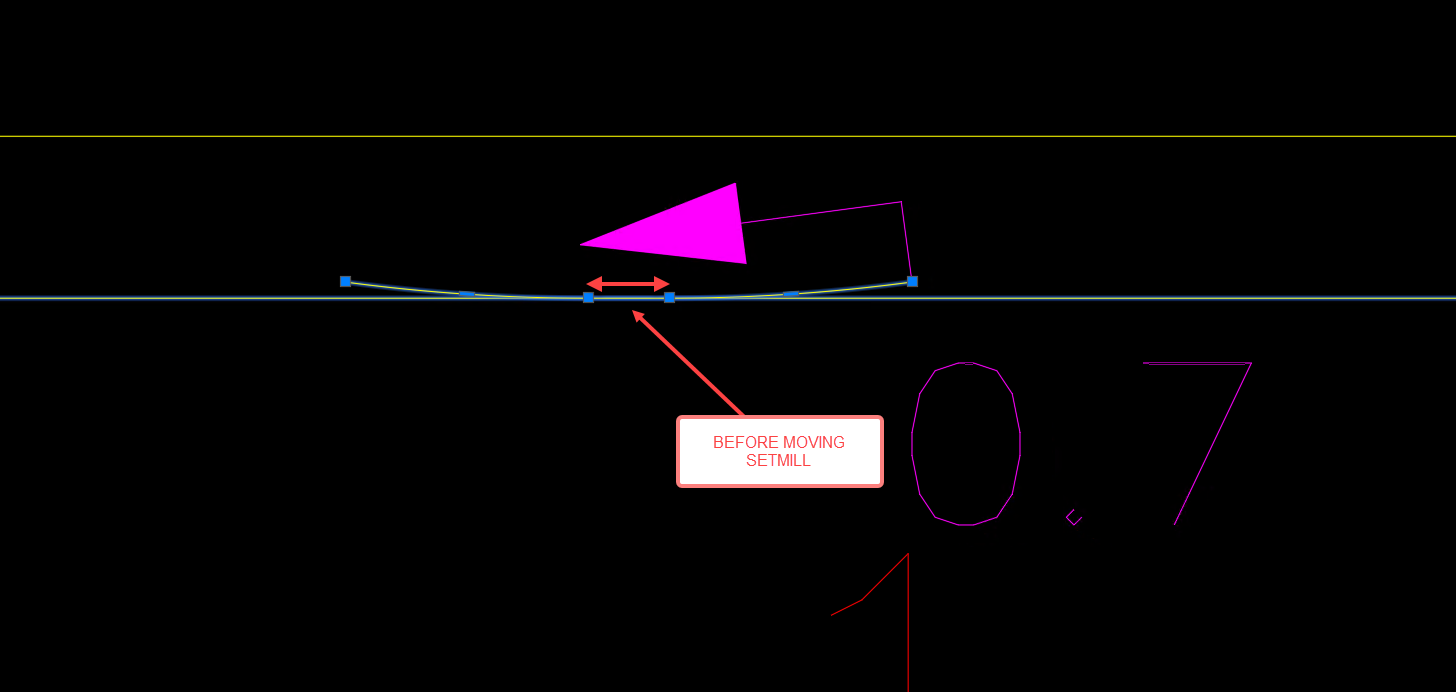

We are running into a major issue with moving the setmill for part borders. The standard lead-in/lead-out has a gap of 0.25 inches between them.

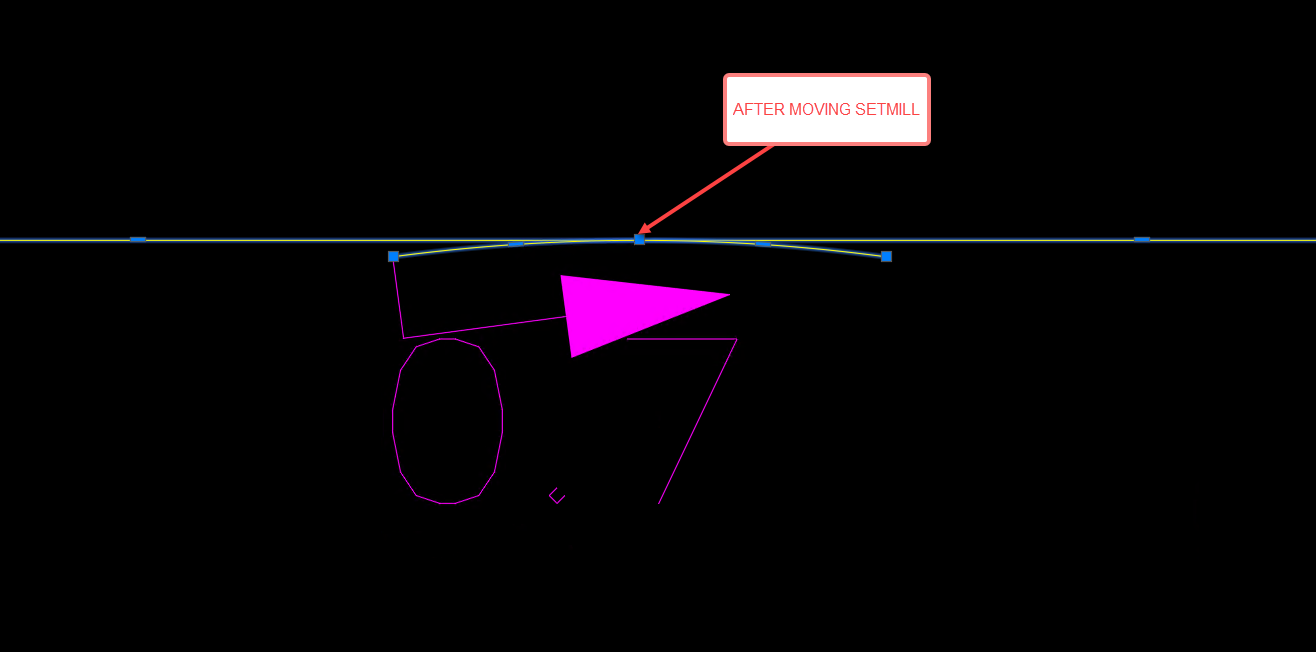

However, when using the Move Setmill tool in the Nesting tools that gap goes to zero.

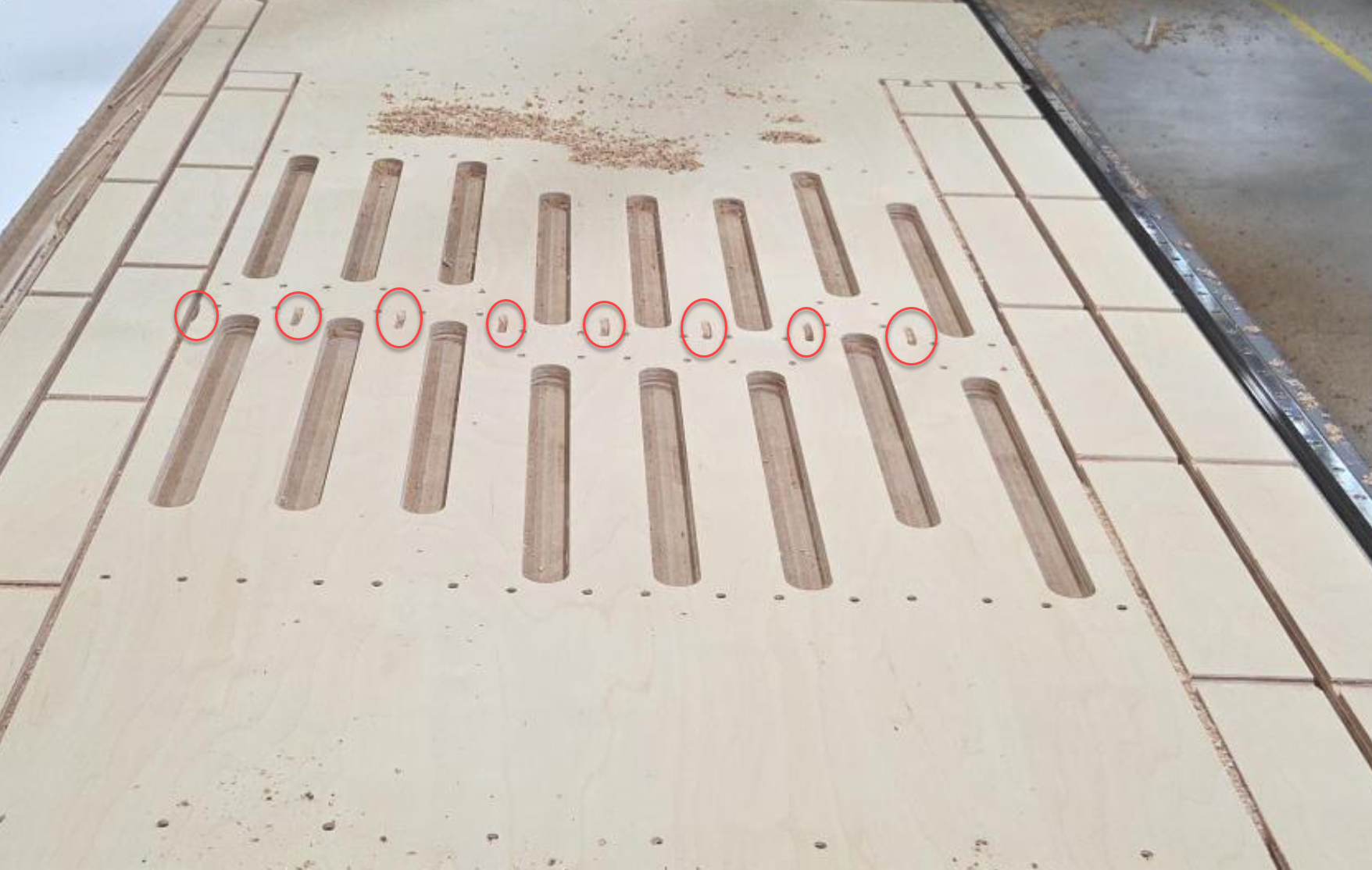

After updating/creating new g-code the border routes are eliminated leaving ONLY the lead-in/out.

This has turned into a very costly issue. Is there a setting somewhere that controls the distance between the lead-in/out? Is there a setting in the post or tool file that is joining vectors stacked on top of each other that would eliminate the border cut?

Any help would be TREMENDOUSLY appreciated.

(FYI, I have a support ticket submitted, but have not received anything back yet.)

After updating/creating new g-code the border routes are eliminated leaving ONLY the lead-in/out.

This has turned into a very costly issue. Is there a setting somewhere that controls the distance between the lead-in/out? Is there a setting in the post or tool file that is joining vectors stacked on top of each other that would eliminate the border cut?

Any help would be TREMENDOUSLY appreciated.

(FYI, I have a support ticket submitted, but have not received anything back yet.)

Topic Participants

James Drury @ Master Millwork

Daniel

Toolbox BSB Survey

Have you been using Toolbox BSB? We'd love to hear what you think!

MVU eLearning

Grow Your Knowledge

Follow along with RJ as he takes you on a journey to build your foundational knowledge of Toolbox.

Follow us on: