How Can We Move Part Border Machining to First Operation?

Admittedly, tool files and posts are not my strong suit. However, I'm in need of a simple process that can be easily trained in engineering and at the CNC. We need to have a Processing Station, tool file, and post that will put the part border operation as the FIRST operation. (Ideally, we'd love to have it also do a hard "pause" at the CNC after the borders are cut and before any other operations continue.)

For instance, we do a lot of miterfolding and we like to do that on the CNC. However, we don't want to cut the part out with the miterfolding at the same time. What we typically do is cut the part out, without miterfolding, edgeband, then place the part back on the CNC using a scored border for alignment.

This process then introduces a mess of steps and operations for engineering. First, we have to nest the panels and remove miterfold machining so the parts can be cut. Then we have to "score" the table again, so the operator knows where to place the individual panels - at this step the parts must have a much larger gap between so the v-cutter doesn't hit other parts. Then we have to add the miterfold machining - without borders - so we don't machine away the edgebanding. Well... removing borders from the nest and creating g-code does not create nest reports, so these sheets end up being printed using MVPN (MV Plot Nests).

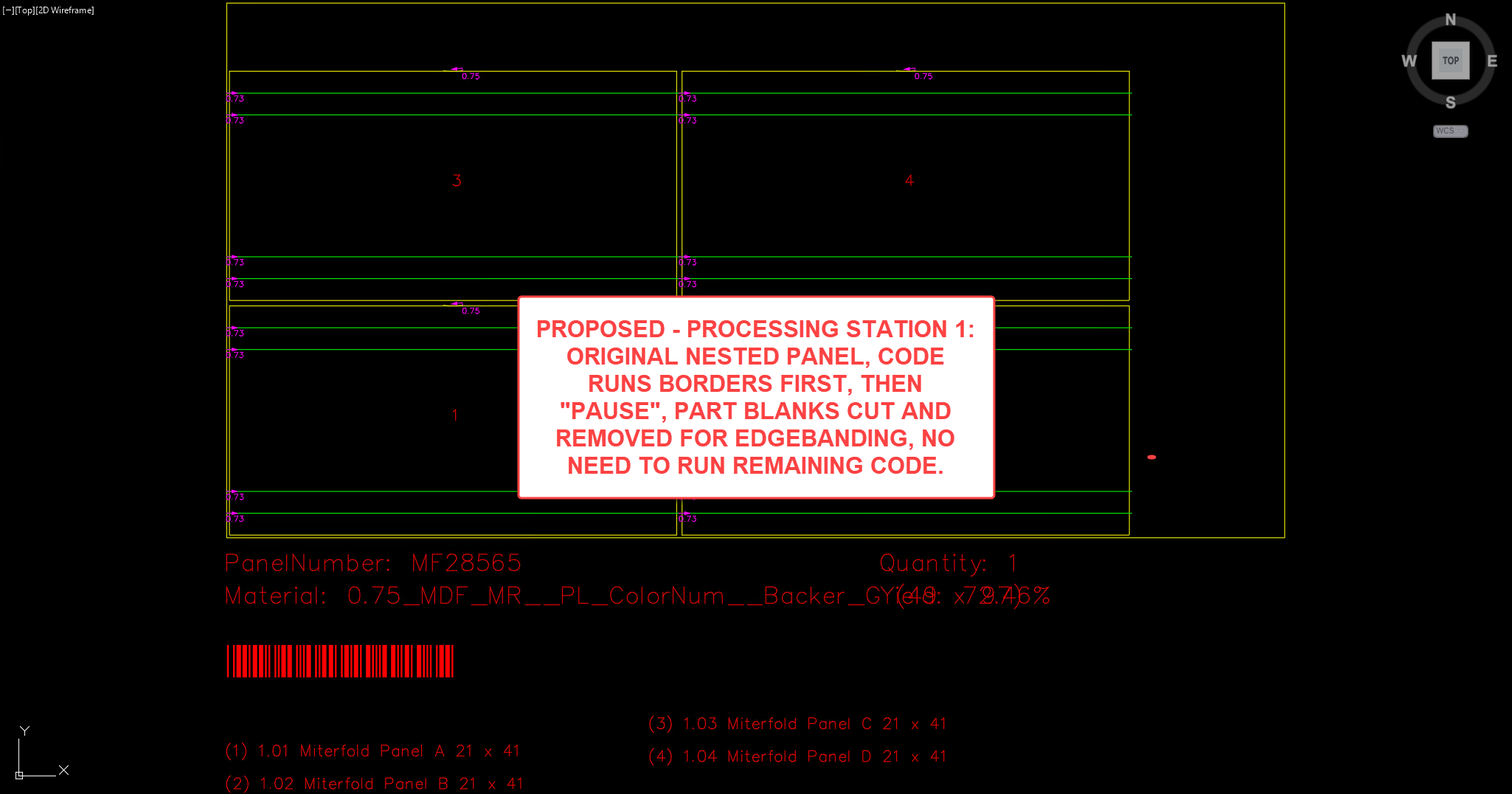

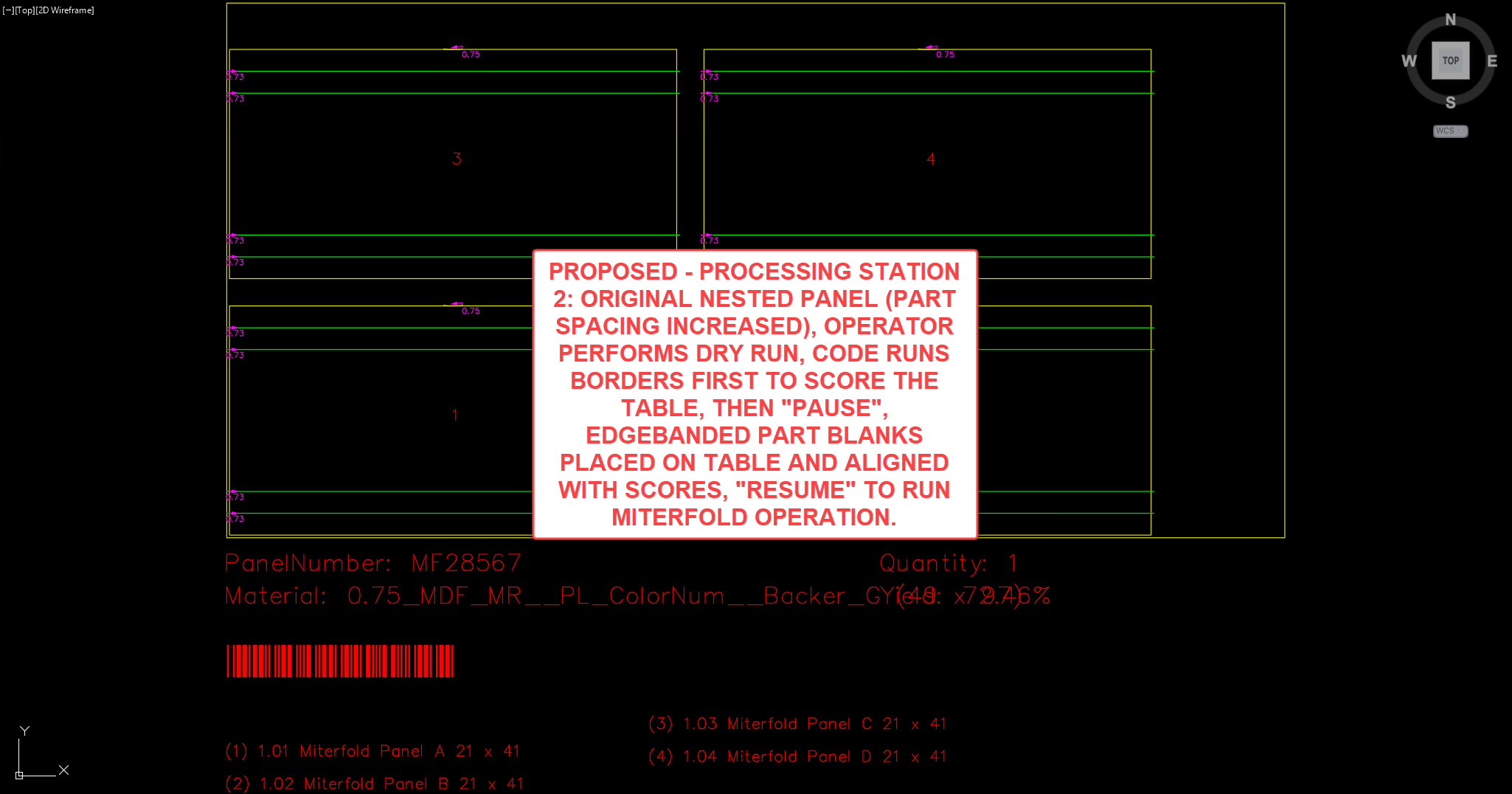

With new engineers and operators, this process becomes nearly impossible to train effectively. HOWEVER, with the ability to do what was mentioned above - borders first, then miterfolding - it allows our engineers to simply nest those parts using two Processing Stations and not have to do anything else. First Processing station cuts the blanks with standard part spacing - with the borders cutting first they can cancel at the "pause". For the second Processing Station - with a wider distance between parts - they can do a dry run of the border sequence to score the table; then at the pause, they can place the panels where necessary and then resume the rest of the sequence.

Current process:

Proposed method - processed by assigning two processing stations to each part:

Simple to train, simple to execute.

Topic Participants

James Drury @ Master Millwork

Gary Balcom

Jacob Edmond

Kyle Fleming

Federico

Toolbox BSB Survey

Have you been using Toolbox BSB? We'd love to hear what you think!

MVU eLearning

Grow Your Knowledge

Follow along with RJ as he takes you on a journey to build your foundational knowledge of Toolbox.

Follow us on: