Configuration Editor: Machining Options

The machining tab contains settings that apply when you create G-Code for a CNC machine. The settings range from setting the current drawing tool file you want to use and accessing the tool file to change additional options with G-Code generation.

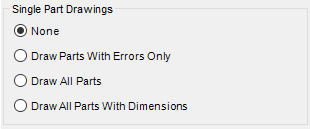

Single Part Drawings

Parts processed with a Single Part G-code station can generate a drawing into a drawing file just like a nest. Processing parts using a single part g-code station creates a parts.dwg file in the material folder of the corresponding work order. The option selected from the single part drawings settings will determine the creation method of the parts drawings.

None – No parts are drawn into the parts.dwg file.

Draw Parts with Errors Only – Draws only parts with errors in their G-Code into the parts.dwg file.

Draw All Parts – Draws all parts into the parts.dwg file.

Draw All Parts with Dimensions – Draws all parts into the parts.dwg file with the dimensions set in the Dimension Settings button, dimension the overall part size, routing, sawing, vertical drilling, and horizontal drilling machining operations.

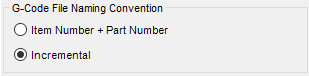

G-Code File Naming Convention

Item Number + Part Number – This naming convention generates more descriptive G-Code file names, but increases the chance for duplicate file names.

Incremental – This naming convention generates a random file name single part G-Code files and ensures that the program creates unique file names.

WMF, DXF Settings

WMF Settings – Properties that control the dimensions for overall part size, routing, sawing, vertical drilling, and horizontal drilling machining operations.DXF Settings – Properties that determine and control how the dimension styles present within a DXF file apply in routing, sawing, vertical drilling, and horizontal drilling machining operations. Changes in dimensions must be made within the DXF template.

Path to DXF Template – Click browse to select the path to the file folder wherein one's DXF template is stored.

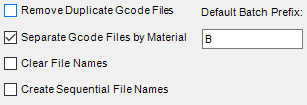

G-Code File Name Options

Remove Duplicate G-Code Files – Compares each G-Code file created for duplicate files. If the program encounters a duplicate G-Code file, all references within the database will match the original file. Removing duplicate G-Code files reduces redundancy and allows a single program for identical parts.

Separate G-Code Files by Material – Creates the G-Code files for nests and single parts in separate folders based on material.

Clear File Names – Clears the default program functionality of assigning file names that match the data specified in the cut parts file, column N, if data exists there. If this checkbox is checked, the program will apply the names specified in the cut parts file. If it is cleared, the program will apply random file names.

Create Sequential File Names – Causes the program to assign file names sequentially instead of randomly.

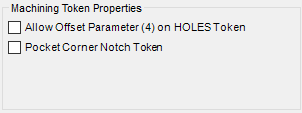

Machining Token Properties

Controls specific machining token properties.

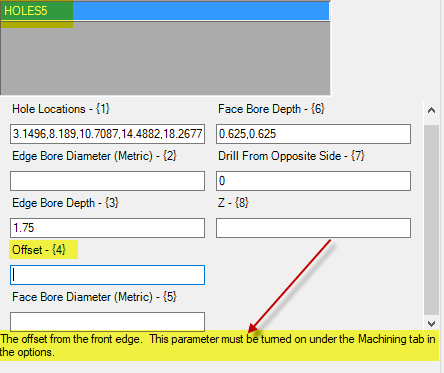

Allow Offset Parameter (4) on HOLES Token - enables parameter (4) of the Holes Token (see Fig. 31)

Pocket Corner Notch Token - sets pocketing for corner notch instead of a cutout.

Related Articles

Overview: Configuration Editor (Options) Interface

The Configuration Editor (Options) Interface for Microvellum Toolbox is accessible from the Toolbox Setup menu. Using the options contained within, you'll configure general system settings, set up the optimization software you use, set up tool files, ...Configuration Editor: Solid Analyzation Options

This article provides an overview of the options and settings available on the Solid Analyzation tab of the Configuration Editor (Options) Interface. For a complete list of available tabs and options visit Overview: Configuration Editor (Options) ...Configuration Editor: Processing Options

This article provides an overview of the options and settings available on the Processing tab of the Configuration Editor (Options) Interface. For a complete list of available tabs and options visit Overview: Configuration Editor (Options) Interface. ...Configuration Editor: General Options

This article provides an overview of the options and settings available on the General tab of the Configuration Editor (Options) Interface. For a complete list of available tabs and options visit Overview: Configuration Editor (Options) Interface. ...Configuration Editor: CAD Options

This article provides an overview of the options and settings available on the CAD tab of the Configuration Editor (Options) Interface. For a complete list of available tabs and options visit Overview: Configuration Editor (Options) Interface. ...

Recent Articles

Microvellum Foundation Library Release Notes | Build 26.0220

The following release notes apply to the Microvellum Foundation Library build 26.0220. Additions Added DTC Magic Pro and Magic Star Ultra drawer systems. Magic Pro Items added in hardware file 300 and 600 lengths for all drawer heights. Add 60kg ...Microvellum Release Notes | Build 25.2.0223.641

The following release notes apply to Microvellum build 25.2.0223.641. Add 2D Elevation Tokens to 3D Drawings Fig. 1: The new 2D Elevation setting. A popularly requested feature by the community has been added to the Microvellum software: the checkbox ...Microvellum Processing Center Application

The standalone Processing Center application provides shop-floor tools for managing and executing manufacturing data generated from Microvellum projects. It enables users to: Print part labels View and print reports Create and re-create manufacturing ...Microvellum Release Notes | Build 25.2.0213.641

The following release notes apply to Microvellum build 25.2.0213.641 File Name Fix An issue was occurring when processing work orders with the Create Sequential File Names setting enabled. When the setting was enabled, a work order being processed ...Microvellum Release Notes | Build 25.2.0206.641

The following release notes apply to Microvellum build 25.2.0206.641. Item Number Fix An issue was reported regarding item numbers in composite drawings. Users who processed work orders with multiple products reported that the item numbers would ...